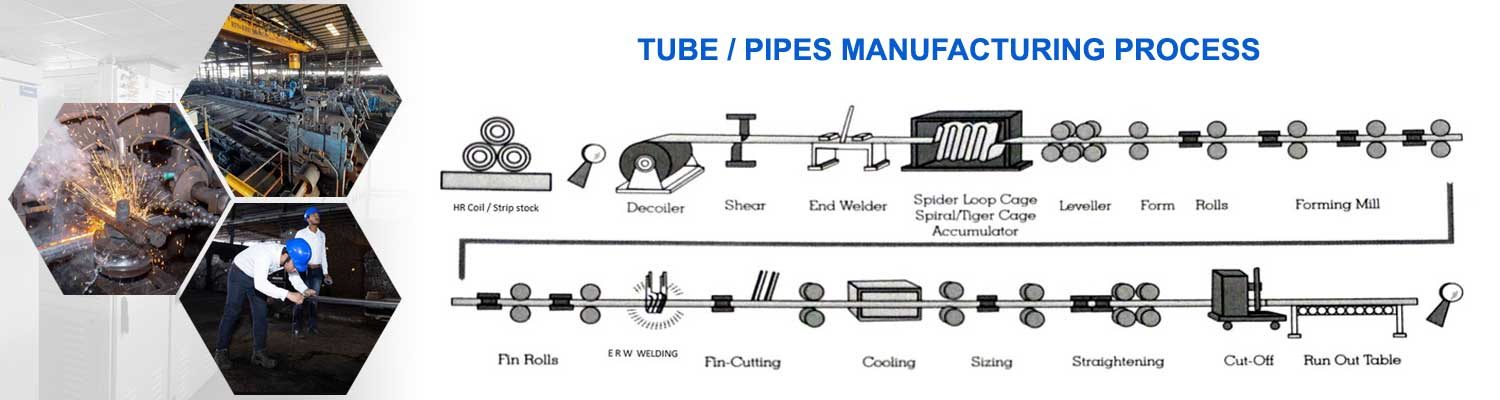

PRODUCTION & TECHNOLOGY

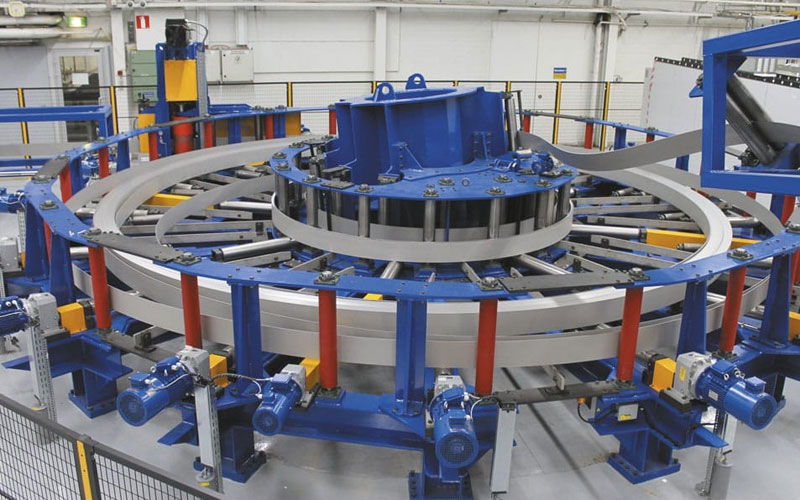

We have invested in contemporary technology at all manufacturing locations. High speed mills configured with electrical equipment from Fuji Gemco, Indo-Japan and Metoweld has ensured cost effective manufacture of a wider product range. Due to superior designs, appropriate layout and latest automation, higher production level can be achieved with consistent quality for all products.

The pioneering backward integration into manufacture of in-house hot rolled coils has opened new markets.

The Company manufactures products to meet Indian and International standards & specifications.

Continuous investment in technology has resulted in

- Low down time & breakdowns leading to high productivity

- Superior yields >95% compared to the industry average of 85-90%

- Proper synchronization amongst machineries provides platform for producing excellent products meeting the exacting requirements of customers

The Company has installed facilities to produce 90,000 tons per annum of mild steel tubes, hollow sections, profiles, guides and structural. The manufacturing facility includes coil slitting, tube making, end facing, shutter profiles & guides.

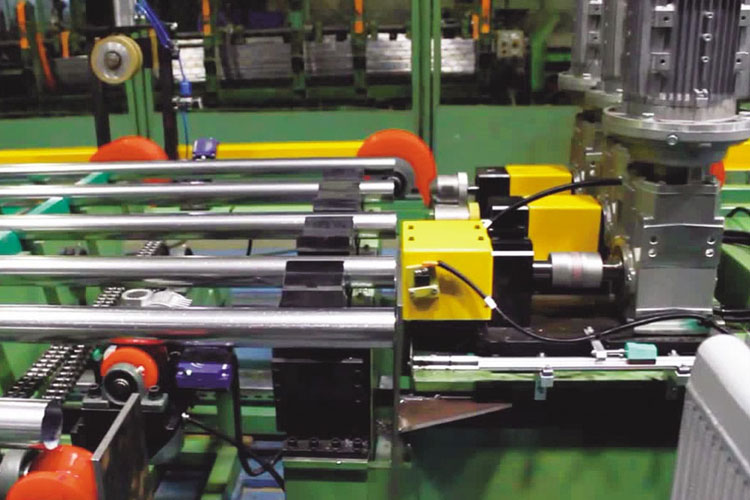

The Tube Mills operate at speed of 90 meters per minute equipped with Eddy Current testing and PLS controls to ensure superior weld quality, straightness and products well within the tolerances specified in respective standards. The quick size changing mill with spare cassettes reduces down time and enables the Company to offer faster delivery.

The Company manufactures products to meet Indian and International standards & specifications. We are also an ISO 9001:2015 Quality Standard Certified company having a strong domestic customer base and exports to over 5 countries.