THE BASICS OF HF WELDING

The two main aspects of HF welding are processes and power supply. Each of these can be broken down further into sub categories.

The two HF welding processes are HF contact and HF induction. In both processes the equipment that provides the electrical current is independent from the equipment that supplies the forge pressure. Also, both HF method con employ impeders, which are magnetic components located inside the tube that help to focus the weld current in the strip edges.

HF Induction Welding

In case of HF induction welding the weld current is transmitted to the material through a work column (please check) in front of the weld joint. The work column does not contact the tube as the electrical current is induced into the material through magnetic fields that surround the tube. HF induction welding eliminates contact marks and reduces setup time when changing tube size. This process ensures less maintenance compared to contact welding.

Steel Tubes/Pipes produced by using this process is called Electric Resistance Welding (ERW) and adopted universally by all tube manufacturers.

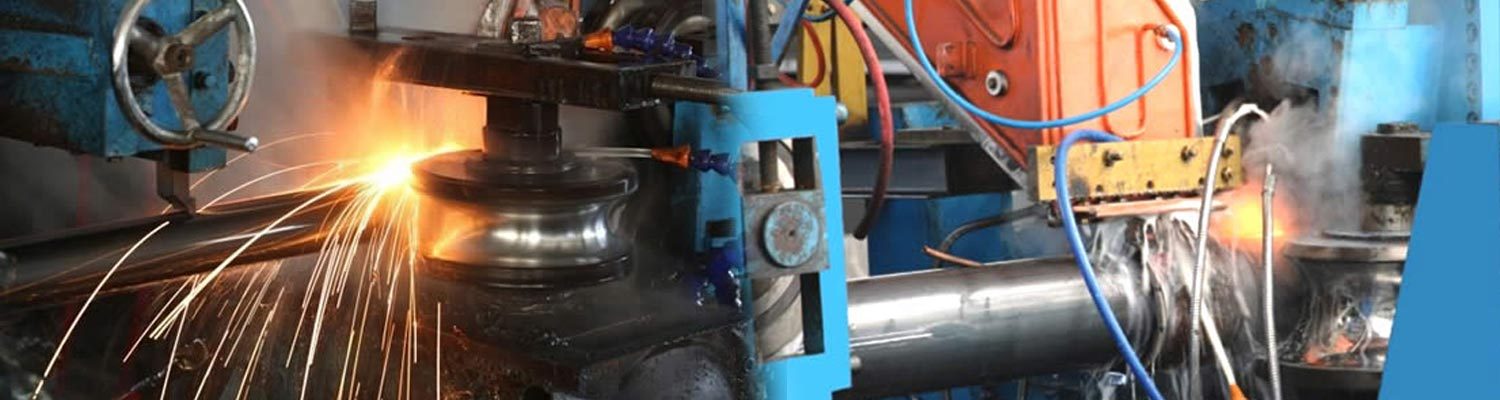

The hot rolled strip is cut to specific width with close tolerance and edges in ideal condition for perfect welding. The slit strip is passed through a number of rolls to form an open seam pipe. The edges of the open seam are heated and welded by a high frequency welding unit. The weld edges are joined together by forcing pressure from rolls. The result is a strong welded pipe like any other metal without change in its chemical composition. Soon after welding a special cutting tool removes the weld flash on the outer surface. The weld flash in the bore of the tube can also be trimmed when specified. Following this would be the straightening process through set of rolls. Thereafter the tubes are cut to the pre-determined length.